Overview

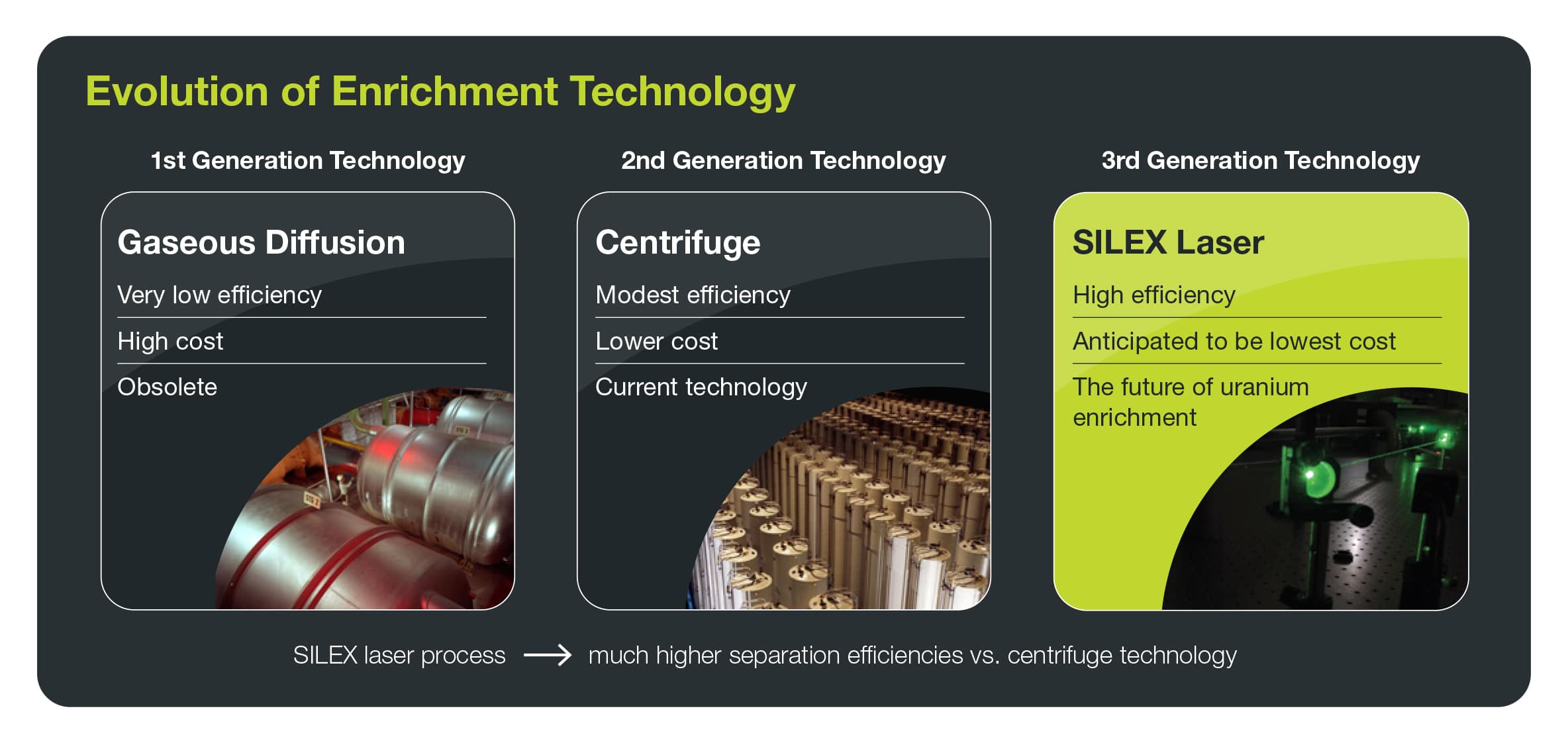

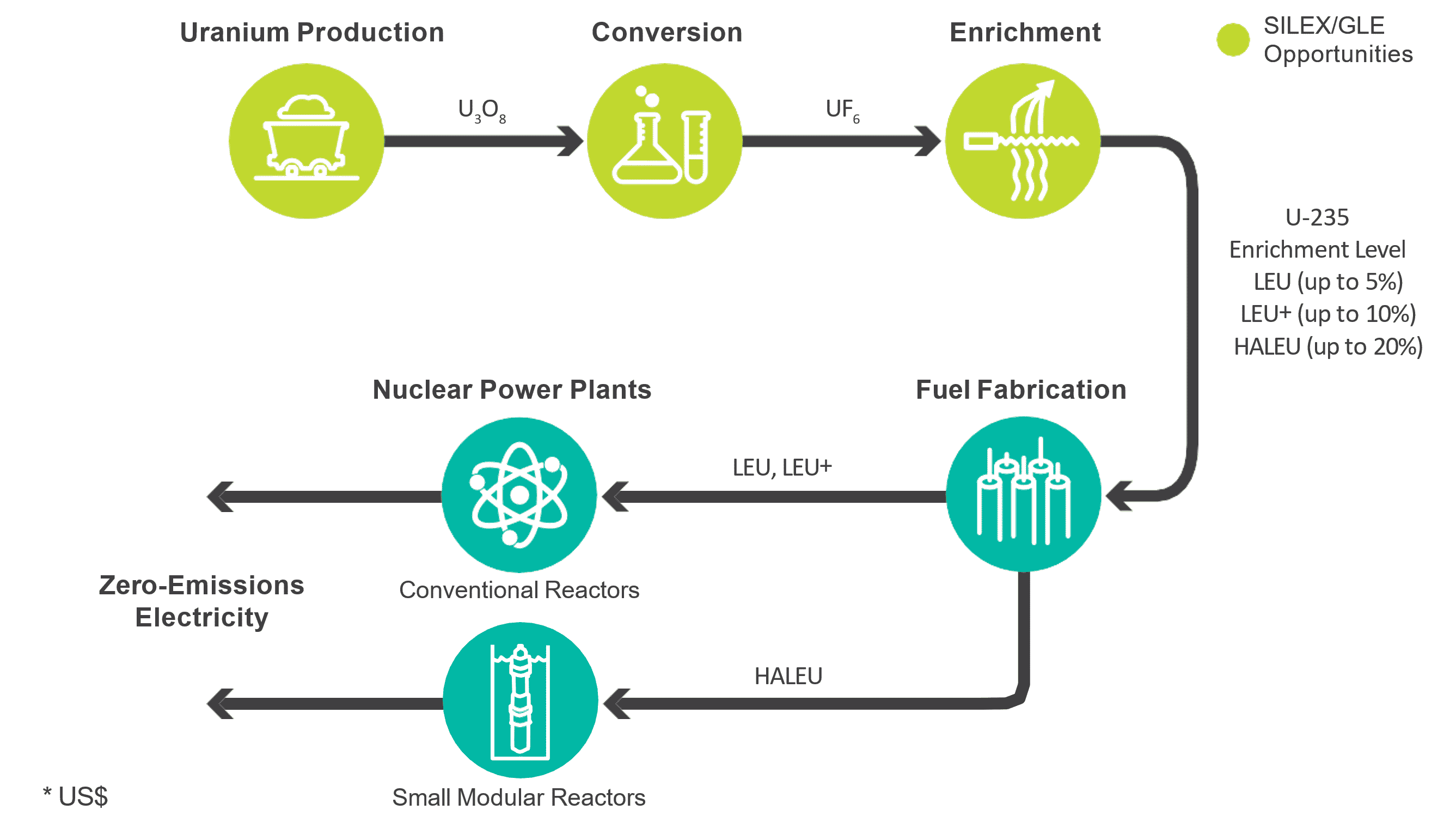

Silex invented and developed the ‘SILEX’ laser isotope separation technology in Sydney during the 1990s. The uranium enrichment application of the SILEX technology was licensed exclusively in 2006 to Global Laser Enrichment LLC (‘GLE’), a joint venture business today owned by Silex (51%) and Cameco Corporation (49%).

GLE’s exclusive worldwide license to commercialise the SILEX technology for uranium enrichment is in accordance with a Technology Commercialisation and License Agreement, amended in 2021. The technology commercialisation project is being conducted jointly at GLE’s Wilmington, North Carolina (NC) facility and at Silex’s Sydney facility, with the current focus on completion of the commercial-scale demonstration of the SILEX uranium technology with a pilot facility being built at GLE’s Test Loop facility.

In February 2023, GLE’s owners agreed to a plan and budget for CY2023 that accelerates activities in the commercial-scale pilot demonstration project for the SILEX uranium enrichment technology.

Since February 2023, Silex and GLE have continued to accelerate construction of full-scale laser and separator equipment being deployed in GLE’s Test Loop facility in Wilmington, with the aim of completing a commercial-scale pilot demonstration (TRL-6) of the SILEX technology as early as mid-2024. Attaining the TRL-6 level is a key milestone in the de-risking of the SILEX technology before the focus turns to the potential preparation for, and construction of, the first commercial SILEX uranium enrichment plant at the PLEF (see Nuclear Fuel Production Opportunities).